|

Ozone film coated composite processing technology

A plastic film

prepress

1. Improve the

printability of the film 2. Ozone film processing works It is now widely understood atmospheric ozone layer is a natural barrier to block the sun's ultraviolet, which is composed of sunlight a particular wavelength spectrum of light irradiation generated after a thunderstorm to a special kind of people will breathe fresh taste is in fact the air increase in the ozone concentration (usually around 0.04PPM) easy to be detected, the reason why the ozone concentration increase, because the lightning (high power) ionizing oxygen in the air to form ozone, forest, tourist areas particularly fresh air, because the plants CO2 absorption process of manufacturing a [O], oxygen atoms in the formation process, some form O2 (oxygen we breathe) part of the O3 (ozone) is the ubiquitous nature of ozone and ultraviolet sunlight in control of bacterial survival balance, protect human health. Human studies have found through the ozone, ozone has unstable characteristics and strong oxidizing ability. Ozone is an oxygen molecule (O2) carrying an oxygen atom (O) component, therefore he is an allotrope of oxygen. Ozone and oxygen, the difference between the table below: Table one of the main properties of oxygen and ozone

Table I. As can be seen, compared with oxygen, ozone than the major, flavored, colored, soluble in water, easy to decompose. Because ozone (O3) is carried by the oxygen molecule composed of one atom of oxygen, determines that it is only a temporary form of portable oxygen atoms in addition to oxidized spent outside, there is a combination of the remaining oxygen (O2) into a stable state. Ozone is a very strong oxidizing substances, the redox potential after F2. Use of its oxidation, can be destroyed in a relatively short period of bacteria, viruses and other microorganisms biological structures, so that loss of viability. So there is no secondary pollution ozone work produced for human environmental needs, this is the biggest advantage of ozone technology. The main application of ozone sterilization in artificially. This is mainly a strong oxidation ability of ozone, oxygen atoms can be oxidized bacterial cell wall, until its body through the wall of the unsaturated bond and seize compound bacterial life, its role is instantly completed, the ozone sterilization effect quickly determine in its high reduction potential, II, shows the reduction potential of the ozone disinfection materials comparison. Table II Comparison redox potential

3 Ozone film

processing

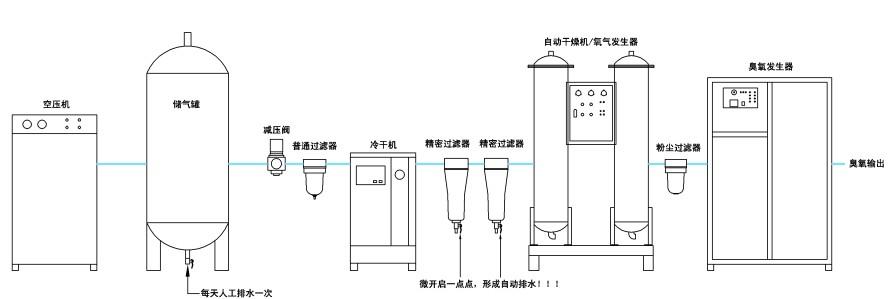

Quality corona discharge method - ozone system is determined by an ozone generator sets from an oil-free air compressor, a Taiwan oxygen generator system, a set of cold and dry air filtration systems and system components. Overall system consisting see "see below."

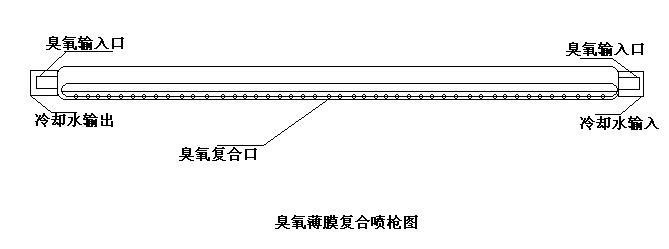

Ozone film composite composite gun diagram:

Clean air output by the oil-free compressor, compressed air filtered through to the general director, after ordinary precision filter, detected by a flow meter and pressure transmitter flow of compressed air and gas pressure, the adsorption dryer depth in addition to water, and then by the addition of water filtered into, so that the dew point gas source to achieve the required 5 - 10 ℃, and then the dust filter allows dust particles less than 1μm, become qualified raw gas source (reach food-grade sanitary permit requirements) . Passing through the raw gas supply valve into the oxygen generator, by pressure swing adsorption method (United States company UOP molecular oxygen as adsorbent) separator exclude the excess nitrogen leaving the remaining oxygen, so the oxygen concentration of 90% before the release of output, to meet the medical standards of high concentrations of oxygen. After entering into the ozone generator, ozone generator in the high-frequency high-voltage venue, oxygen (O2) conversion of ozone (O3), product gas is ozone gas, the flow rate, the pressure regulating valve adjustment and vortex flowmeter, pressure transmitters and temperature transmitters detect flow, pressure, temperature, and ozone monitoring instrument detects ozone concentration, ozone generator ozone generated by the vortex and the manifold pressure transmitter to detect total flow and pressure into the water-cooled ozone composite pipe. Ozone injection technique using a porous composite pipe direct contact with the film to ozone oxidation, thus greatly improving the adhesion of the film.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| back next | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Copyright © http://www.laiter.com.cn Corporation and its licensors. All rights reserved. Guangzhou Ozone Technology Co.,Ltd |